in this case an acronym, “L(ive) O(ak) S(ide) T(able)”. More obscure would be to combine the non-leading letters … iveAkIdeAble. All that would be missing is that which is lost.. 🙂

I had a nice piece of live oak, roughly 4 feet by a foot and a half. In the living room there was a piece of cumaru atop four milk crates that served as a side table. I love milk crates for their utility, configurability, etc, but don’t think it proper to live in a milk crate constructed world, first class for a third world though it may be. The fullness of time gradually plays out and so I came to this creation. The first idea, knee-jerk, was to give it four legs, much as tables are wont to have, pictured below with the pieces held in arrangement by gravity, a very temporary arrangement.

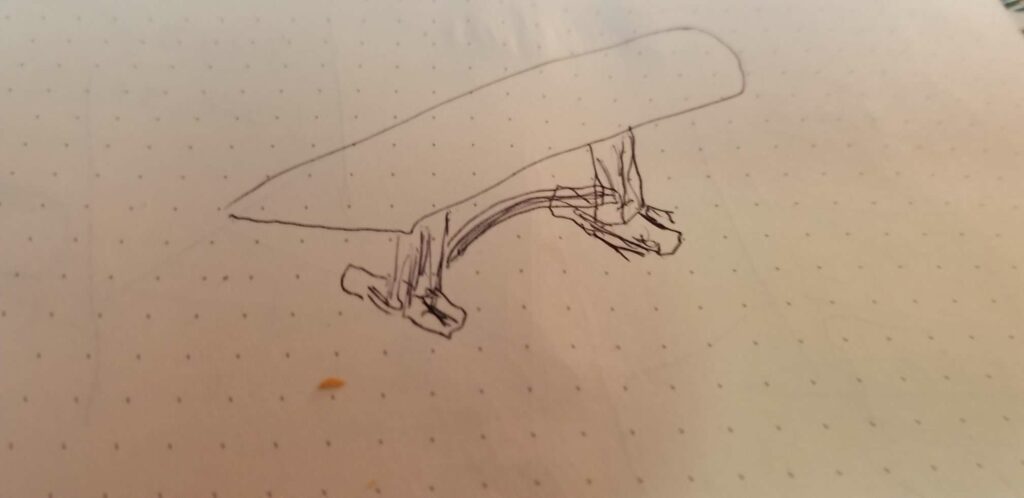

I shared the idea. Generally the feedback received was the legs weren’t right. Ever attentive to nuanced appreciators, let me say that again, a-sketching I went, looking to appease the collective muse. We know that sometimes rationalists don sombreros. I think that’s what the muse was getting at, that the standard four square didn’t really go with the free flow top.

The drawing seemed to satisify. Undertaken was the challenge.

One of the four legs I turned into two feet, another repurposed as a crossbar. The wood of all these not live oak but rather of fairly old (harvested originally ~1820, upcycled from a fallen barn in 2020, born from an acorn likely sometime in the life of that scourge of indigenous “Christopher Columbus”.

My preferred woodworking principle is no metal. While screws are strong their aesthetic is so weak. The ankles here got me in trouble, relative to those principles. I used half inch dowels from the bottom up into the legs. Those didn’t stop the unacceptable level of play. A better design could have solved but I’d rushed forward (or backward) too fast. From the bottom again I drilled shallow 3/8 holes and inside those drove 3 inch screws, two for each leg. High stability was achieved. I plugged the 3/8 inch holes with bits of walnut dowel. Sin hidden but not much of a fig leaf. The same sin repeated in attaching the leg assembly to the table top. Behold the shame!

Kind eyes see differently, or at least one hopes. Compromises ignored, the result appears decent to me.

and so there is the tale. My primary learning was to be a little more cautious in assumptions about the functional characteristics of a design. I like the table though, it’s just an easy show off of a nice piece of wood.

All the best to you dear readers.